ANT Hot Regeneration of Asphalt Technology

The ANT Hot Regeneration of Asphalt Technology developed by ANT-Engineering company is unique for several factors and unrivaled in the world. The technology allows to use RAP (granulated asphaltic concrete) in the amount of 30% to 99.9% of the total weight to produce regenerated asphalt mixtures. This is made possible by means of molecular rejuvenation of bitumen, which is contained in RAP (crushed asphalt), at the molecular level. This approach allows to lower the estimated production cost of regenerated asphaltic concrete by more than a half, as well as solve a number of environmental challenges.

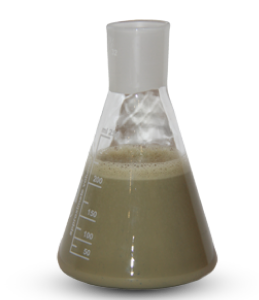

ANT Organic Regenerator of Asphaltic Concrete

The main element of the technical process is the agent ANT Hot Regeneration of Asphalt Technology (further ANT Regenerator) manufactured by ANT-Engineering company. This is a complex organic preparation. It is aimed to perform reactions of reduction-oxidation at the molecular level in RAP (granulated asphalt). As a result of this process, the surface of the asphaltenes is destroyed and new hydrocarbon compounds of low molecular weight are formed. The new regenerated asphalt acquires higher rates of physical and mechanical properties, high adhesion to the cold layers and the possibility of compaction at the temperature of the mixture of 70°С. The consumption rate of the ANT Regenerator is 0.05% to 0.15% of the RAP weight. The recommended consumption rate is 0.1% of the RAP weight. The agent is used in a concentrated form. No additional bitumen or cement are required.

The uniqueness of the ANT Hot Regeneration of Asphalt Technology

01

The Use of RAP in the Amount up to 99.9%.

The ANT Organic Asphalt Regenerator makes a directed reaction of reduction-oxidation, which results in a rejuvenation of the bitumen that is contained in the RAP. If it is necessary to improve the composition of the regenerated asphaltic concrete, you can add stone materials as well as bitumen.

02

Possible Use of Various Equipment.

Regenerated asphalt mixtures can be prepared in all models of recyclers provided with a heating system, as well as in mixing installations, which have a continuous action mode. The basic requirements are heating the RAP, dosing the ANT Regenerator, and mixing the components.

03

Low Costs

The price of 1 ton of asphalt, which is regenerated and prepared under the ANT Technology, is more than 50% lower than the cost of manufacturing a new asphalt mixture under a standard technology. The economy is achieved owing to the use of RAP in the amount up to 99.9% of the total weight of the asphalt regenerated.

04

Environmental Safety

The ANT Asphalt Regenerator is completely safe for man and nature. The use of the technology allows creating new asphalt mixtures by reusing the waste generated in the process of milling worn asphaltic concrete.

05

Execution of Works in a Non-Stop Mode

Once the regenerated asphalt layer is compacted, the road traffic, including trucks, can be started with an intensive load. No maintenance of the new layer is required.

06

Possible Repair of Asphalt Coatings in the Winter Period.

Owing to the use of the ANT Regenerator, the asphalt regenerated acquires new properties, such as the ability of the mixture to compact at the temperature of 70°С, as well as high adhesion to the cold asphalt layers. The repair of asphalt coatings can be performed therewith all year round, even in winter at air temperatures of down to - 15°С.